Laser cutting machine creates acoustic guitar, opening a new era of musical instrument processing

When it comes to traditional acoustic guitars, people who love playing guitars will immediately think of the top two brands: Martin (Martin) and Taylor (Taylor). The status of the two in the guitar is equivalent to the Ferrari and Porsche in the car.

In today's fast-changing technology, the production process of guitars is also constantly developing. Whether it is Martin, who has a history of more than 150 years, or Taylor, who has only been established for more than 40 years, they are now using laser technology to participate in the production of guitars. Let the tradition keep up with the changes of the musical instrument era in the process of continuation.

The more advanced the instrument, the finer the craftsmanship. In addition to the high requirements for guitar wood selection, the technical requirements are more rigorous. The top is the main part of the guitar structure, and the precision with which it is cut also affects the tone. As long as the top shape or size differs by an inch, the guitar parts will not fit together properly and the sound will be out of shape. When traditional manual technology is combined with advanced laser technology, the product can perfectly achieve the desired effect in terms of structure and material characteristics.

According to the computer design drawings, the laser equipment accurately cuts the size of the wooden board structure designed by the R&D team. The non-contact processing method will not damage the high-quality veneer material, and the edge is smooth and free of burrs, which reduces the subsequent grinding and finishing steps, and also protects the workers from scratching their hands when completing the guitar assembly and splicing, realizing machine production. Coordination with humanized production.

The laser cutting machine makes the guitar with beautiful shape and smooth lines. With its exquisite craftsmanship and unique viewing, it is loved by guitar manufacturers and players. At the same time, it saves production costs and improves efficiency for musical instrument manufacturing and processing, and promotes musical instrument manufacturing into a new era of digital processing.

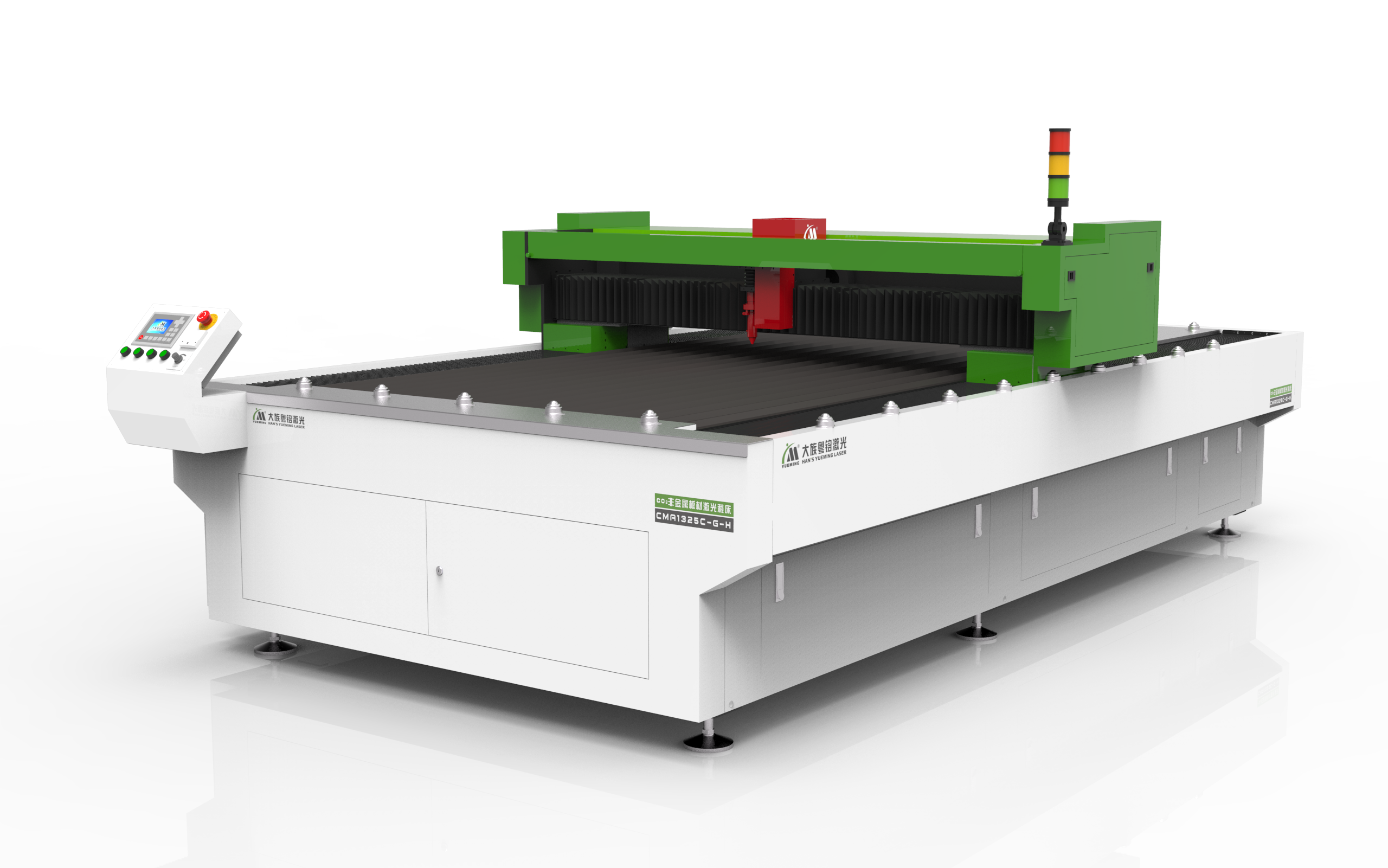

Recommended equipment: non-metallic sheet laser cutting machine

Non-metallic sheet laser cutting machine

Features of non-metallic sheet laser cutting machine:

◆Full rack and pinion kinematic structure

◆High precision cutting

◆High speed running stability

Process application of non-metallic sheet laser cutting machine:

Cutting and cutting of large-format non-metallic plates such as wood board, wood plywood, MDF, acrylic board, etc.