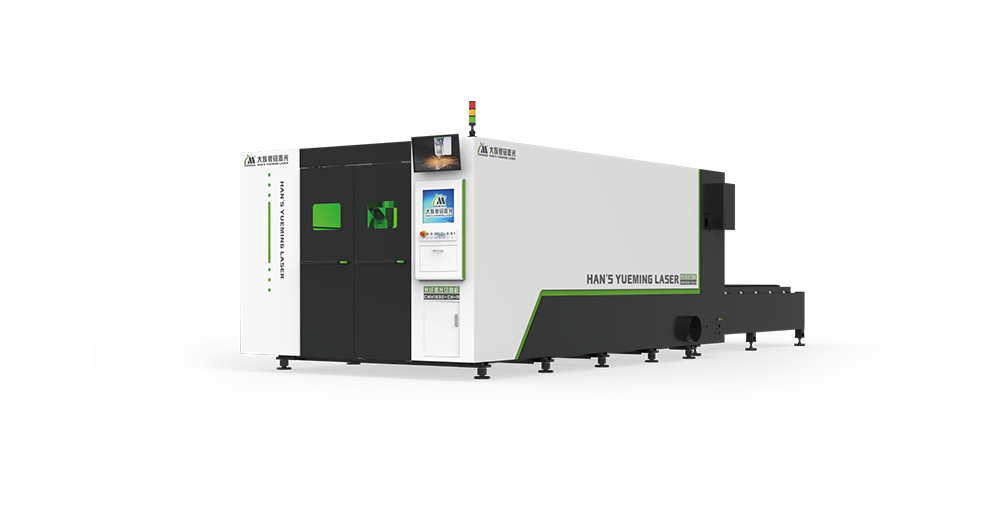

Enclosed Combo Fiber Laser Cutter for Sheet & Tube CMO1530-CHR-B

Laser power(w)

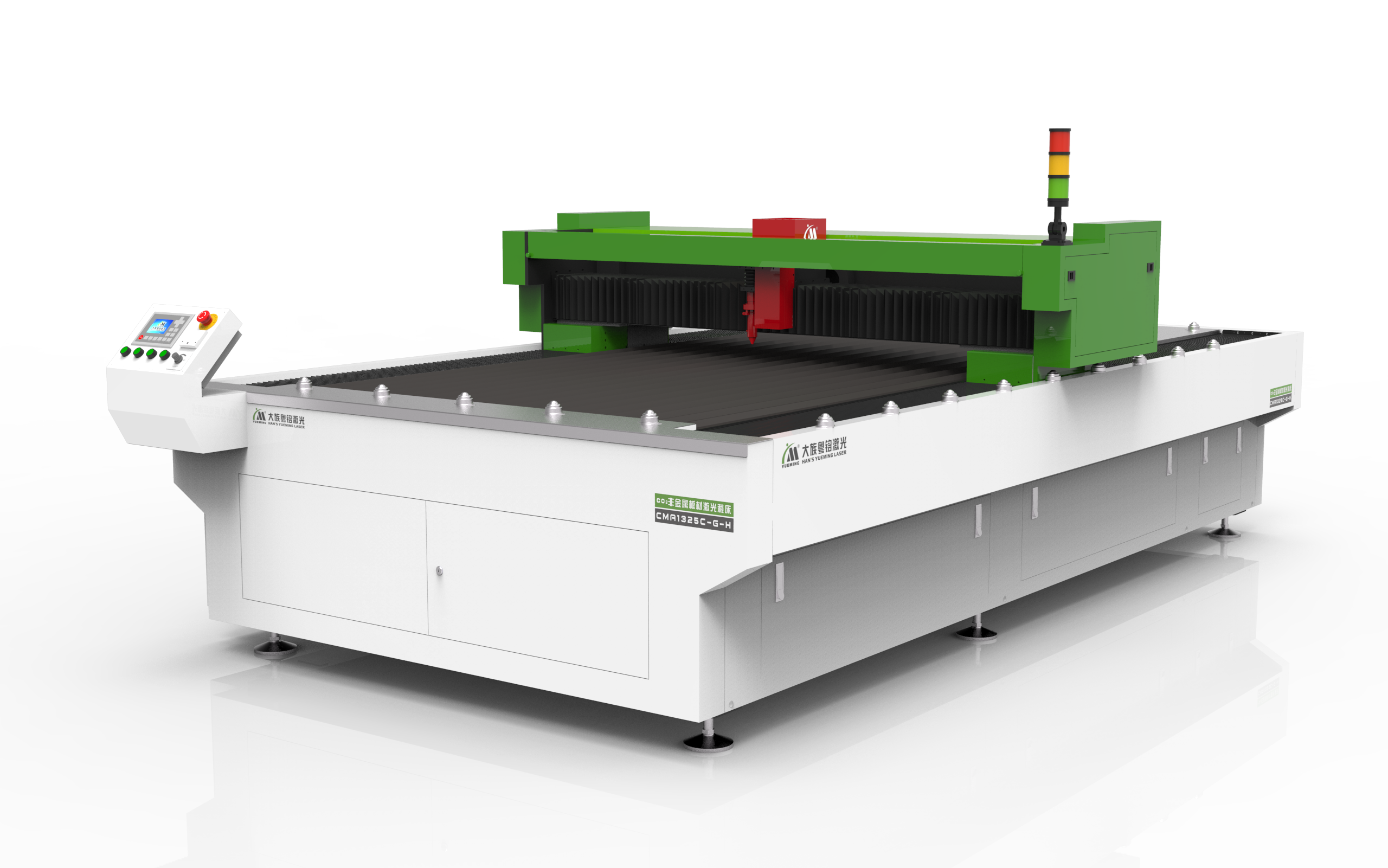

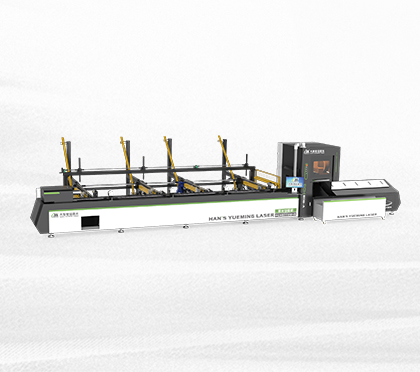

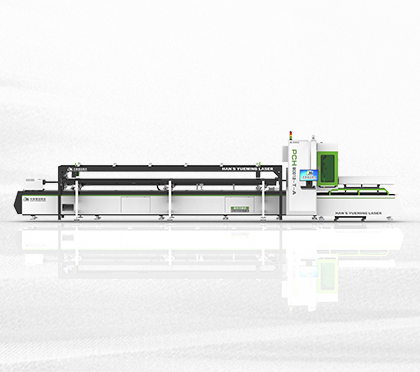

Han's Yueming Laser Interactive Plate and Tube Integrated Fiber Laser Cutting Machine is equipped with a pneumatic self-centering chuck, which can realize symmetrical independent double-action clamping without manual intervention and adjustment during the clamping process; it adopts an enclosing outer protection design to effectively protect the work. Safety of personnel; processing formats are available in 1500x3000, 2000x4000, and 2500x6000. Classic applications - elevator stainless steel cutting, stainless steel tube laser cutting, etc.

- Advantages

- Video

- Parameter

- Application

Advantages

Integrate multi-function into one , create more value for customer

-

01

Rack and pinion transmission system, dual-servo drive, effectively improve the equipmemt production efficiency;

-

02

The equipment enjoy power failure memory; retreat cutting; automatic fault alarm and emergency stop; fault info auto-display;

-

03

Auto-focus head, flexible piercing technique, support auto change focal position in piercing, suitable for thick metal plate processing;

-

04

Support offset tube center error in production to improve through holes cutting precision;

-

05

Enclosed protection cover to prevent the dust and fume go outside, ensure the operator could have a friendly working environment;

-

06

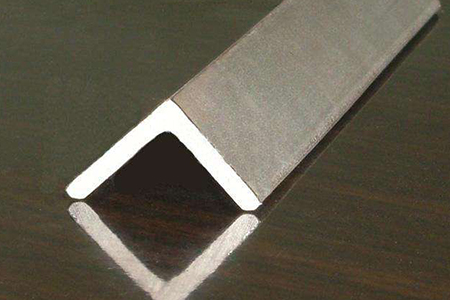

Suitable for sheet and tube processing, software can help to Auto Find Tube Center in Production, and enjoy Active Control at Corner Cutting;

-

07

Mchine tool: large gantry milling, 600℃ heat treatment , 24 hours cooling inside the furnace to ensure the steel welded joint stress relief, then guarantee the machine tool long term accuracy and stability.

Parameters

Optimization and innovation, make product faster, more stable and more assured.

| Model | CMO2560-CHR-B | CMO2040-CHR-B | CMO1530-CHR-B |

|---|---|---|---|

| Laser power(W) | 2000-4000 | 2000-4000 | 2000-4000 |

| Working area(mm) | 2500×6000mm | 2000×4000 | 1500×3000 |

| Overall dimension(mm) | 13500×4700×2100 | 11000×4200×2100 | 8600×3700×2100 |

| Positioning accuracy(mm) | ±0.03/1000 | ±0.03/1000 | ±0.03/1000 |

| Repeated positioning accuracy(mm) | |||

| Speed(m/min) | 100 | 100 | 100 |

| Maximum accelerated speed | |||

| Claw clamping weight(kg) | |||

| Pipe diameter range(mm) | φ20-φ220 / φ10-φ150 | φ20-φ220 φ10-φ150 | φ20-φ220(标配) φ10-φ150(可选配) |

| Maximum duct length | 6000mm | 6000 | 6000 |

| Gross power(kW) | 14 | 14 | 14 |

| Weight(kg) | 12000 | 10500 | 9000 |

| Supply voltage | 380V/50/60Hz | 380V/50/60Hz | 380V/50/60Hz |

| Working environment | Temp: 0~45°C Humidity:≤80% Clean | Temp: 0~45°C Humidity:≤80% Clean | Temp: 0~45°C Humidity:≤80% Clean |

Application

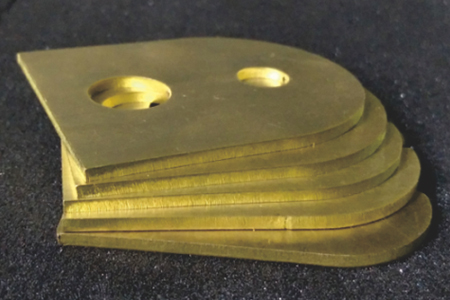

Metal materials such as Carbon steel, Stainless steel, Aluminum alloy, Titanium alloy, Galvanize sheet, Brass, Red copper etc.