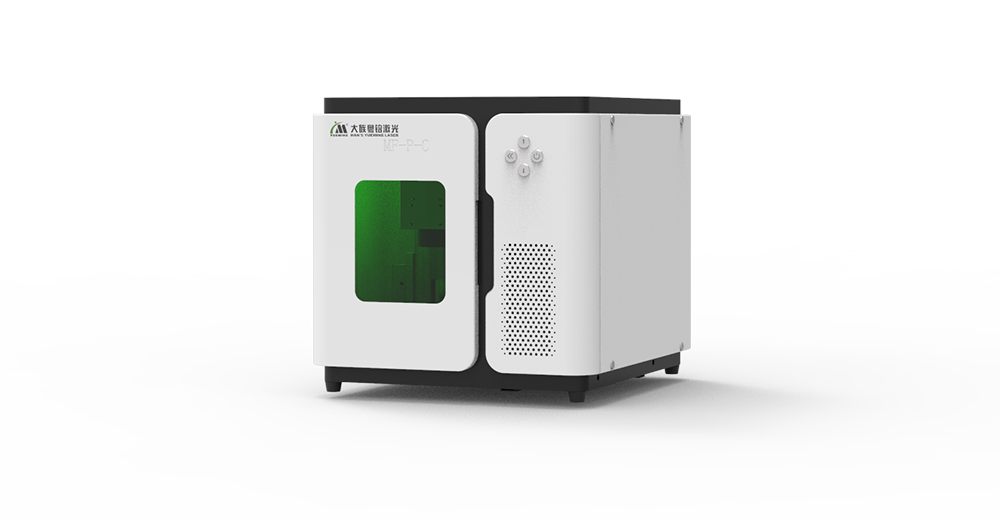

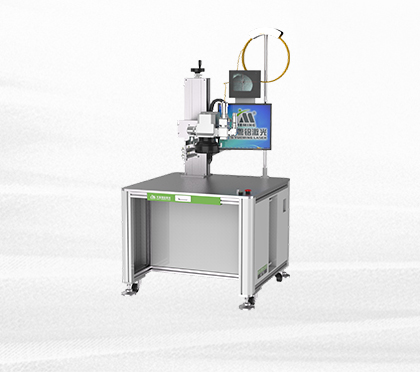

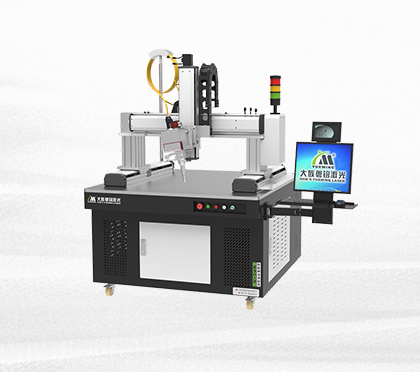

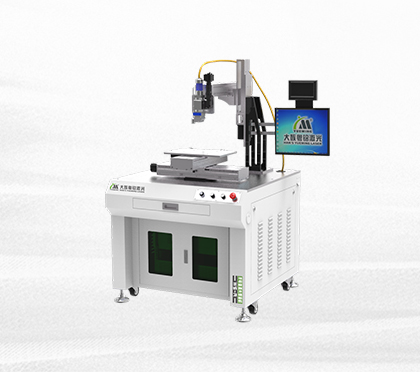

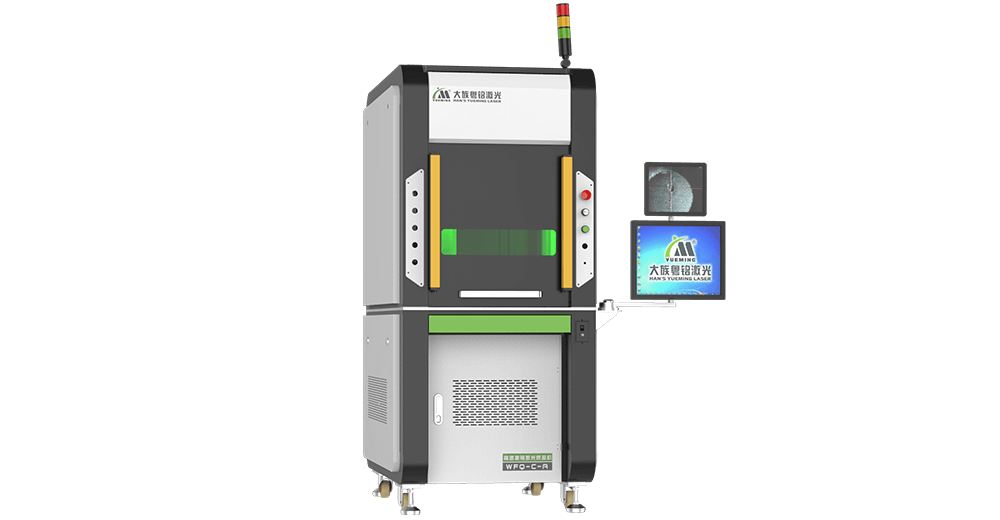

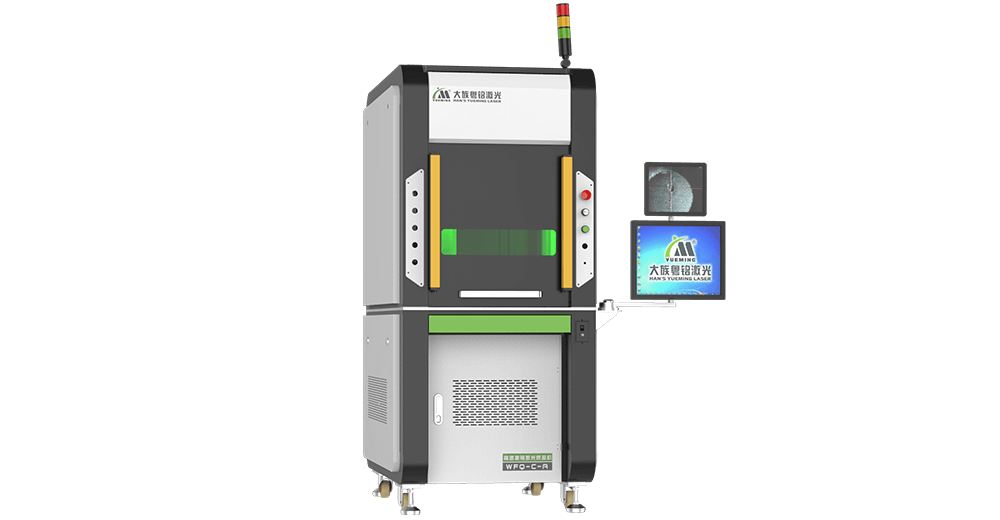

Galvo High Speed Welding Machine QCW

Laser power(w)

Han's Yueming Laser high-speed galvanometer laser welding machine adopts industrial computer as human-computer interaction, which can perform non-contact long-distance welding, and the operation is simple and reliable; the high-quality galvanometer system is faster than the traditional XY axis platform in single-point welding; the same Axis CCD camera teaching and positioning function, can quickly and accurately find solder joints; mainly used in 3C electronic components welding, battery tab laser welding, new energy and other industries laser welding applications.

- Advantages

- Video

- Parameter

- Application

Advantages

Integrate multi-function into one , create more value for customer

-

01

Adopts IPC remote control, easy for operation;

-

02

Galvo welding system is much faster than XY moving platform

-

03

Coaxial CCD camera teaching positioning helps to fast and preicisely locate the welding spot;

-

04

Low running cost, less consumables, and simple daily maintenance;

-

05

Optional welding heads to adapt for different customers’requirement;

-

06

Flexible laser system, easy for intregation on other production lines.

Parameters

Optimization and innovation, make product faster, more stable and more assured.

| Model | QCWwelding laser | Continuous welding laser |

|---|---|---|

| Laser power(W) | 1500/3000W | 500w |

| Laser wave length(nm) | 1070 | 1064 |

| Fiber diameter(μm) | 14 | 14 |

| Cooling method | (Water Cooling / Air cooling) | Water Cooling |

| Maximum single-point energy | 15/30J | / |

| Overall dimension(mm) | 1000*100*1900 | 1000*100*1900 |

| Weight (Kg) | 200 | 200 |

| Total power | ||

| Supply voltage | 220V,50HZ | 220V,50HZ |

| Working environment | (Storage temp): -20°C~30°C;(Humidity): <70% (Working temp): 10°C~35°C;(Humidity): <70% | (Storage temp): -20°C~30°C;(Humidity): <70% (Working temp): 10°C~35°C;(Humidity): <70% |

| Gross power(w) | 150/300 | 500 |

| Fiber diameter | (standard): 10mm (Optional): 15mm | (standard): 10m (Optional): 15m |

Application

Mainly apply for welding on 3C parts, battary welding and new energy industry;